SPST Switch in Electrical Systems Benefits and Applications

Advantages and Disadvantages

Advantages and Disadvantages

Benefits of Using SPST Switches

Simplicity and Ease of Use

One of the main advantages of SPST switches is their simplicity and ease of use. These switches’ design are simple, they are usually composed with an actuator and a pair of contacts. So even a guy only knows the basics of electric can figure it out. Apart from that, their intuitive ON/OFF functionality ensures that users can quickly understand and utilize them, reducing the likelihood of operational errors.

Cost-Effectiveness

SPST switches are also known for their cost-effectiveness. Easier the design is, less the components are, hence, less cost of manufacture. This is an economic benefit that makes SPST switch a budget-friendly choice for many occasions, and it will pass on to consumers and the entire industry. Besides, SPST switch have a rather long lifespan, which save the need for frequent replacements and repairs, which further enhancing their cost-efficiency. And because SPST switches are affordable, they are widely used in consumer electronics, automotive systems, and industrial equipment.

Potential Limitations

Limited Functionality

Despite their many advantages, SPST switches have some limitations, particularly regarding their functionality. They are designed for basic ON/OFF control and do not offer advanced features such as multi-path routing or variable control that are available in more complex switch types. This simplicity means that SPST switches cannot be used in applications requiring intricate control mechanisms. For projects that need more than just basic circuit interruption or completion, alternative switch types like SPDT (Single Pole Double Throw) or DPDT (Double Pole Double Throw) are more suitable.

Application Constraints

Another limitation of SPST switches is their application constraints. They are ideally suited for low to moderate power applications and might not be appropriate for high-power or high-voltage scenarios. Using an SPST switch beyond its rated capacity can lead to overheating, arcing, or even switch failure. Therefore, while selecting an SPST switch, it is imperative to consider the electrical ratings (voltage and current) to ensure safe and reliable operation. This constraint necessitates careful planning and sometimes the need for additional components like relays in more complex systems.

RFecho

RFecho

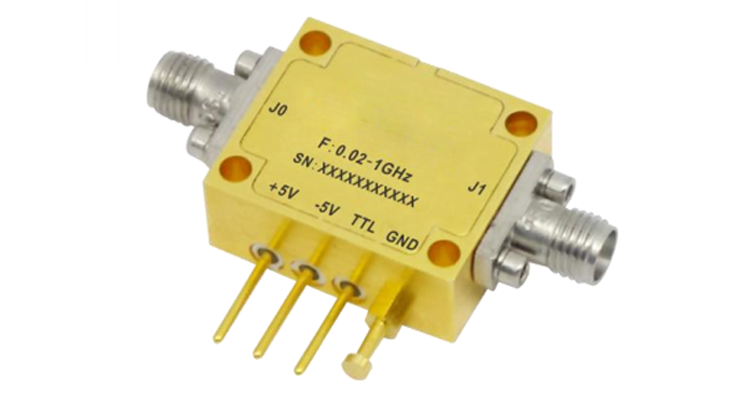

One of the standout products in RFecho’s extensive portfolio is the Single Pole Single Throw (SPST) Switch. This switch, a testament to RFecho’s engineering expertise, is recognized for its simplicity and efficiency. It controls the flow of current in a circuit using a straightforward on-off mechanism, making it an ideal choice for applications that demand reliable and uncomplicated switching.

The SPST switch from RFecho is constructed with top-tier materials, ensuring durability and long-term performance. It is meticulously designed to meet the rigorous demands of modern high-frequency applications, making it a preferred choice among technicians and experts globally.

In the context of electrical systems, the SPST switch offers numerous benefits. Its simple design reduces the chances of malfunction, and its easy operation makes it user-friendly. Moreover, its ability to control the flow of current with a simple on-off mechanism makes it highly efficient and reliable.

Installation and Maintenance Tips

Proper Installation Techniques for SPST Switches

Necessary Tools and Equipment

To install an SPST switch properly, a few essential tools and equipment are required. These typically include a screwdriver, wire stripper, multimeter, and electrical tape. Safety equipment such as insulated gloves and safety glasses is also recommended to prevent accidents. Selecting the appropriate switch for your application and checking its electrical ratings against the system requirements is crucial. Adequate planning and preparation ensure that the installation process is smooth and that the switch operates effectively.

Step-by-Step Installation Guide

Safety First: Turn off the power supply to the circuit where the SPST switch will be installed to avoid electrical shocks.

Prepare Wires: Strip the insulation off the wires using a wire stripper, revealing enough conductor to make a secure connection.

Connect Wires: Attach the wires to the switch’s terminals. Ensure that the connections are tight and secure to prevent any loose contacts that could lead to malfunction.

Mount the Switch: Fit the switch into its designated housing or switch panel and secure it using screws. Ensure that it is firmly mounted to avoid it becoming loose over time.

Inspection and Testing: Once installed, use a multimeter to check for continuity and proper operation. Turn the power back on and test the switch by cycling it between ON and OFF states to ensure it works correctly.

Regular Maintenance Practices

Regular maintenance of SPST switches is essential to ensure their reliability and longevity. Periodic inspection is recommended to check for any signs of wear and tear, such as frayed wires or corroded contacts. Cleaning the contacts using an appropriate contact cleaner can help maintain good electrical conductivity. Additionally, tightening any loose connections and inspecting the switch housing for cracks or damage can prevent potential failures. Implementing these maintenance practices ensures that the SPST switches continue to perform efficiently over their operational lifespan.

Comparing SPST with Rocker, Toggle, and Push Button Switches

Comparing SPST with Rocker, Toggle, and Push Button Switches

When comparing SPST switches with other types like rocker, toggle, and push-button switches, several key differences and similarities arise. Rocker switches and toggle switches often utilize the SPST mechanism but differ in their form factor and user interface. For instance, a rocker switch operates by rocking a lever back and forth, while a toggle switch pivots on a central axis. Push-button switches can also function as SPST, offering momentary or maintained configurations depending on the design. The choice between these types often depends on the specific application and user preferences. Rocker switches are common in household appliances due to their ergonomic design, while toggle switches often appear in industrial settings for more robust operations. Push-button switches are frequently used in control panels and consumer electronics where compact switch profiles are advantageous.

Practical Applications in Various Industries

Use in Consumer Electronics

In consumer electronics, SPST switches are commonly found due to their straightforward operation and reliability. Devices like televisions, audio equipment, and gaming consoles use SPST switches for power control. Additionally, they appear in household appliances such as coffee makers and blenders, where simple ON/OFF functionality is essential. Their ease of integration and cost-effectiveness make them a popular choice for product designers aiming to deliver dependable performance without unnecessary complexity.

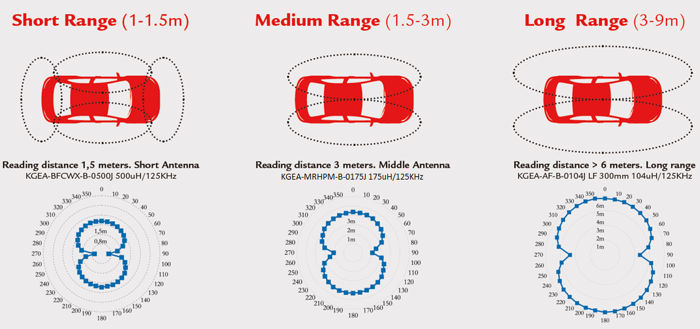

Role in Automotive Systems

The automotive industry extensively employs SPST switches for various functions. These include headlight controls, window mechanisms, and ignition systems. The reliability and simplicity of SPST switches suit the demanding environment of vehicles, where durability and consistent performance are critical. In modern vehicles, SPST switches also contribute to driver and passenger convenience by enabling straightforward control over numerous electronic subsystems.

Implementation in Industrial Equipment

In industrial settings, SPST switches find application in machinery and equipment control panels. They are particularly useful in situations where straightforward ON/OFF control is required, such as starting and stopping motors or activating conveyor belts. Their robustness ensures they can withstand the harsh conditions often present in industrial environments. Furthermore, SPST switches’ simplicity aids maintenance and minimizes downtime, contributing to more efficient and reliable operations.

Summary and Final Thoughts on SPST Switches

In conclusion, SPST switches play a vital role in various electrical systems due to their simplicity, cost-effectiveness, and reliable performance. While they have some limitations in terms of functionality and application constraints, their benefits often outweigh these drawbacks for many applications. Proper installation and regular maintenance ensure their long-term efficiency and durability. By understanding the differences between SPST and other switch types, as well as recognizing their practical applications across different industries, one can make informed decisions about their use. Whether in consumer electronics, automotive systems, or industrial equipment, SPST switches continue to be an essential component in the realm of electrical control.

Advantages and Disadvantages

Advantages and Disadvantages RFecho

RFecho Comparing SPST with Rocker, Toggle, and Push Button Switches

Comparing SPST with Rocker, Toggle, and Push Button Switches