Understanding the Mechanics of a DPDT Switch in Electronic Circuits

DPDT switches play a role, in circuits by enabling different setups to enhance the flexibility and precision in how devices operate. These Pole Double Throw (DPDT) switches work by creating two circuits that can link to one of two outputs each time users need to handle various operational modes. In this piece take a look at the workings of DPDT switches as we examine their structure, functionalities, and the guiding principles behind their operations with a special emphasis, on DPDT push button switches.

Overview of DPDT Switches in Electronic Circuits

Definition and Functionality of DPDT Switches

DPDT switches are devices that manage the flow of electricity, in circuits using two poles and connections to two outputs – the name “double pole double throw.” This setup enables the switch to control devices or alter the direction of flow in a circuit as needed. Users can. Close circuits by switching the DPDT switch making it crucial for applications requiring connections like machine control and remote systems.

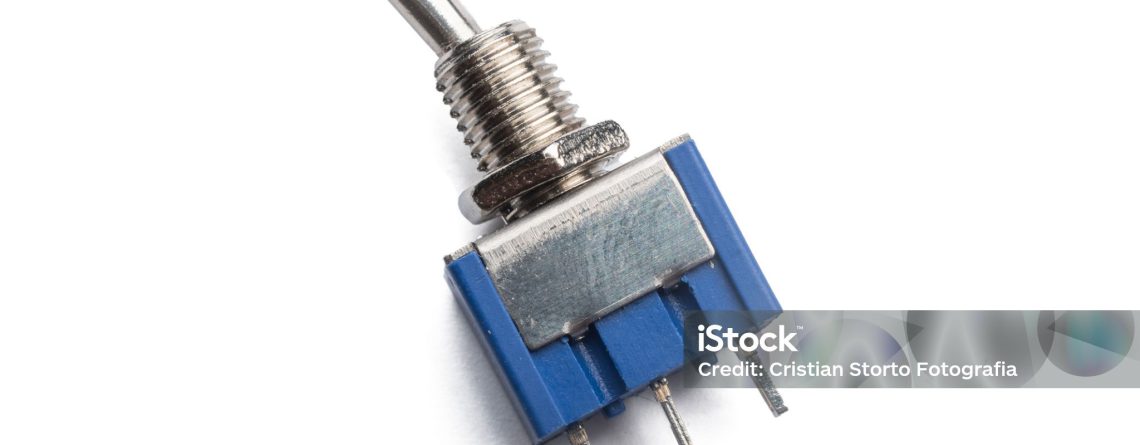

Key Components and Construction

The DPDT switch is made up of parts, like the switch body and terminals with an actuator mechanism in the shape of a lever or push button included as well. The terminals connect to both the power source and the load while the actuator enables users to change the position of the switch. Internal contacts within the switch. Disconnect these terminals to control power flow as needed. Durability is a factor, during design to ensure it can handle operations throughout the lifespan of the device.

Understanding Different Modes and Configurations

DPDT switches can be set up in ways and modes of operation to meet requirements, in electronic circuits. The two main setups are maintained and momentary actions; maintained switches stay in place once activated while momentary switches go back, to their default position after being released. Knowing about these setups is important when choosing the switch for a project or application to make sure it works well with the circuit design.

The Working Principle of a DPDT Push Button Switch

The Working Principle of a DPDT Push Button Switch

Electrical Operation and Signal Pathways

The way a DPDT push button switch works is, by changing how electricity flows through paths when you press the button.The internal contacts of the switch move to connect the circuit to one of two outputs when you press it. This action changes the direction of the flow, in the circuit. This electrical process involves creating or interrupting pathways to control how the circuit behaves depending on the switch’s position.

Common Applications in Circuit Design

Switching Between Different Power Sources

A typical application involves switching, between power sources; for instance, a gadget might require running on a battery or an AC power source by integrating a DPDT switch into the circuit design to facilitate smooth transitions, between these power sources without requiring intricate wiring configurations.

Reversing Motor Directions

In addition, to that is using DPDT switches to reverse motor directions which can be done by modifying the connections of the switch to change the direction of a DC motor rotation making it beneficial in fields like robotics and machinery that need control over directionality showing how important DPDT switches are, in designing circuits.

When it comes to applications today it’s possible to improve circuit design by using reliable components such, as those provided by RFEcho. RFEcho is known for its selection of devices designed for circuits including sturdy DPDT switches that meet strict criteria for performance and longevity. Their items go through quality checks. Are crafted with ease of use, in consideration. When searching for switches that can easily fit into systems or uncomplicated setups. RFEcho offers a variety of options, for professionals and hobbyists alike They are known for their dedication to creativity and quality which has made them a reliable ally, for engineers looking to maximize the capabilities of electronic circuits.

To put it simply having a grasp of how DPDT switches work is crucial, for individuals involved in circuitry. These switches play a role in designs due to their capability to manage multiple pathways and functions. Whether it’s about switching power sources or changing the direction of motors the significance of DPDT switches in control is undeniable. As technology progresses the demand for devices such as DPDT switches will likely increase, solidifying their position, in the realm of engineering.

Integrating DPDT Switches with RFecho Products

Integrating DPDT Switches with RFecho Products

Compatibility Considerations with RFecho’s Product Line

When incorporating DPDT switches, into systems or devices it is crucial to ensure compatibility with the components being used RFecho offers a range of DPDT switches that are tailored to integrate smoothly with different circuit layouts These switches are meticulously crafted to meet industry standards guaranteeing consistent and dependable functionality, in any setting Engineers who opt for RFecho products will appreciate that their DPDT switches come with pin configurations and electrical ratings that seamlessly match up with commonly utilized components making the design phase more straightforward and efficient

Moreover, RFechos pole-thrown switches offer compatibility, with various voltages and currents to meet a wide range of project requirements spanning from simple electronics to intricate machinery. With dimensions, these switches can seamlessly slot into existing designs without requiring any alterations thereby simplifying the integration process considerably. Considering the alignment of RFechos products, within an engineer’s design context can greatly enhance project efficiency. Guarantee effectiveness overall.

Benefits of Using RFecho’s DPDT Switch Solutions

Enhanced Reliability and Durability

RFechos DPDT switches are favored for their reliability and durability due, to the high-quality materials used in their manufacturing process that resist wear and tear over time. This longevity leads to extended lifespans. Decreased frequency of replacements and downtime in electronic systems—especially vital, in safety-critical applications where equipment failure could have severe repercussions. Users can rely on RFecho switches to ensure that their circuits will maintain performance, across operational scenarios.

RFechos design also incorporates locking mechanisms in models to prevent unintended switching and improve their dependability even more greatly. Engineers can trust that their circuit’s integrity will remain intact in these conditions. When users opt for RFecho products they are essentially making a commitment, to components that adhere to the performance and safety standards, throughout their lifetimes.

Ease of Installation and Maintenance

When using RFechos DPDT switches, in circuits it’s easy to integrate them thanks to their compatibility and user-friendly design that prioritizes installation and upkeep tasks like wiring connections are made easy with clearly labeled terminals and intuitive markings that help engineers and technicians identify functions quickly for quicker setup and reduced errors, during installation.

Maintenance is made easier because of how simple these switches are to work with and how they are built for access, to parts for troubleshooting and repairs – reducing the hassle involved in these tasks. RFecho offers documentation and support materials that are incredibly useful, for professionals needing to carry out inspections or replacements promptly. As a result, the design philosophy followed here focuses not only on setting up but also on ensuring easy usability throughout the entire lifespan of the product.

Advanced Tips for Efficient Use of DPDT Switches

Optimal Soldering Techniques for Secure Connectivity

When working with DPDT switches and solder joints it’s crucial to apply the methods, for creating long-lasting connections. Having a connection is key to maintaining flow and reducing resistance, in the circuit. Make sure to prep the parts by cleaning the pads and removing any rust or impurities that could cause connections. Additionally, it’s important to use the temperature on your solder iron; low a temperature might not melt the solder properly while too high a heat can harm the components.

Engineers should also think about using flux to improve solder flow and enhance quality; making sure that the solder covers both the lead and pad surfaces completely creates a bond that can withstand vibration and thermal expansion effectively. It’s essential to allow for cooling time well because rapid cooling may lead to fragile joints. By following these methods RFecho DPDT switches, in circuits can deliver performance.

Troubleshooting Common Issues Encountered During Operation

The use of high-quality parts, in place and the ability to troubleshoot problems that occur when operating DPDT switches is a skill for any engineer to have in their arsenal toolbox. One common problem that often crops up is connectivity issues which could be due to solder connections. An examination of the solder joints and fixing any weakened links through reflow can frequently solve these issues. Moreover, you should always double-check for voltage levels, within the circuit as variations can result in behavior.

A frequent problem arises when the switch breaks down mechanically because of wear and tear caused by pressure, on the actuator lever over time. It’s crucial to stick to the recommended usage limits for the switch to keep it working well. In case a switch stops working suddenly conducting tests outside of the circuit can help pinpoint whether the issue stems from the switch itself or, from the circuit layout. RFecho provides troubleshooting assistance that can assist engineers in resolving issues promptly and successfully.

Maximizing Efficiency in Complex Circuit Designs

In circuit layouts, it’s essential to maximize the effectiveness of DPDT switches, for results. Engineers must grasp the roles of each switch in the system to place them strategically for flow regulation. When creating circuits, with DPDT switches it’s crucial to consider how their states interact to prevent conflicts that might cause circuit malfunctions.

Using simulations to simulate switching actions can offer insights into the setup before actually putting it into practice physically.RFechos DPDT switches are particularly well suited for simulations thanks to their electrical properties. Furthermore having labeling and detailed documentation, in place, during the design stage helps with troubleshooting later on. By approaching the design process and taking advantage of RFechos products the efficiency of overall circuit performance can be greatly improved by engineers.

In summary incorporating DPDT switches, into circuits from RFecho’s range of products provides exceptional flexibility and precision in diverse use cases. Through grasping compatibility by utilizing reliability and simplicity in upkeep, proficiency in solder work, troubleshooting skills, and refining design approaches engineers can guarantee the success of their endeavors. RFecho emerges as a top-notch option for individuals looking for excellence and creativity, in parts consistently backing the changing realm of technology and circuit layout.

The Working Principle of a DPDT Push Button Switch

The Working Principle of a DPDT Push Button Switch Integrating DPDT Switches with RFecho Products

Integrating DPDT Switches with RFecho Products